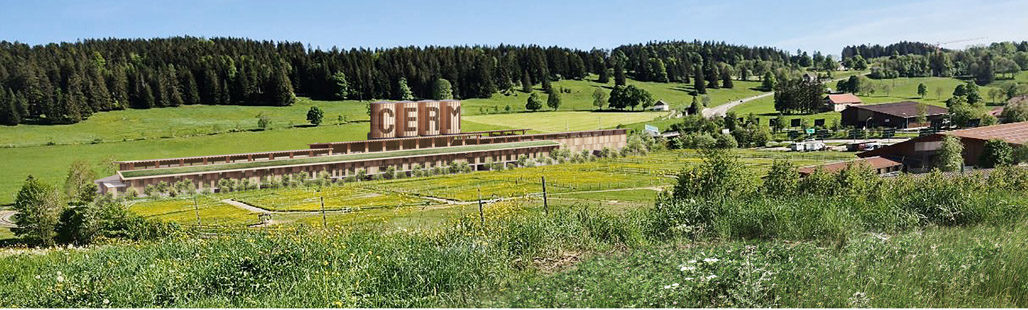

Absinthe Frappé : Infrastructure building, Competition, La Chaux-de-fonds, Switzerland

Absinthe Frappé : A New building for the maintenance of roads.

The maintenance centers and road depots in the upper canton of Neuchâtel are no longer efficient or suitable for maintaining the road networks in the region, and they will not be sufficient for the maintenance of the new sections to come. Therefore, it is essential to create a new center dedicated to the maintenance of cantonal and national roads (CERM).

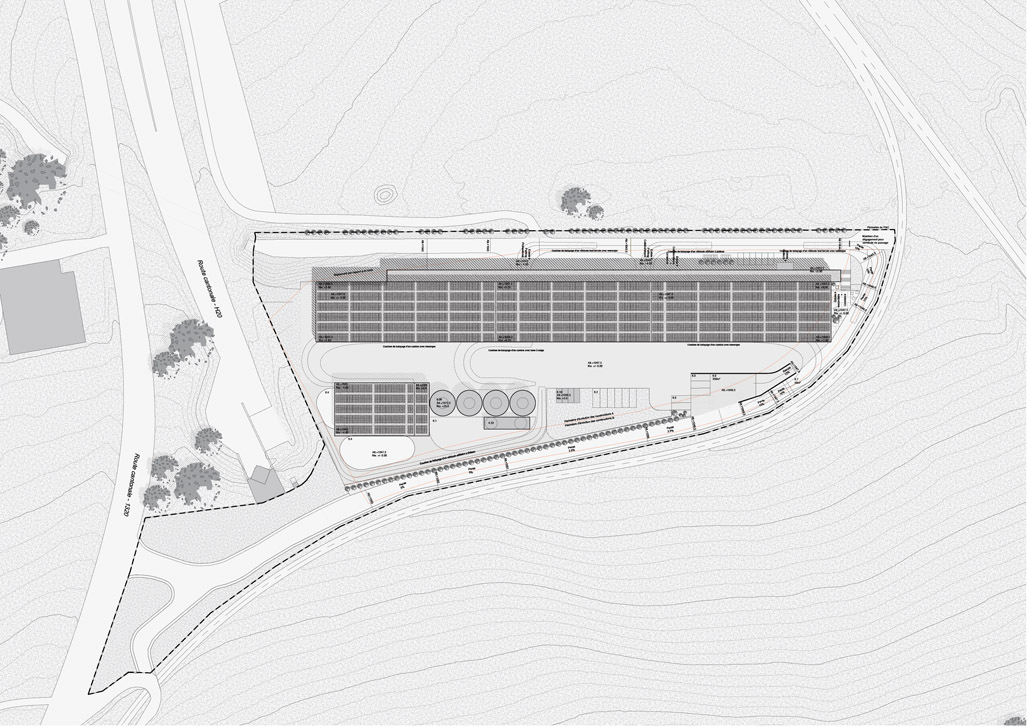

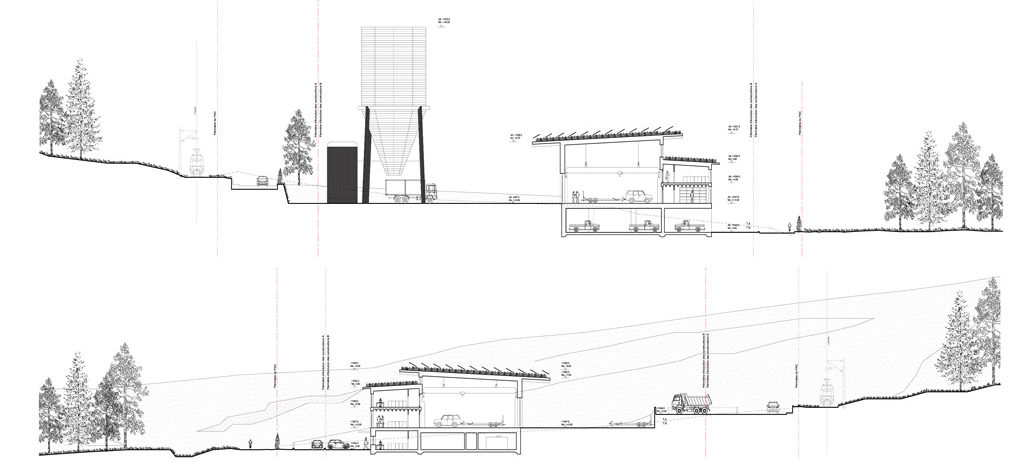

The area identified for the construction of the project is located at the southeast entrance of the city of La Chaux-de-Fonds. The land is situated at an altitude of 1,050 meters on a gently sloping terrain. The plot offers a total surface area of 25,911 square meters and is located at the intersection of road networks, in connection with the future bypasses of La Chaux-de-Fonds and Le Locle. The construction of this mixed-use center dedicated to the maintenance of cantonal and national roads (CERM) is necessary.

Rational Industrial Organization

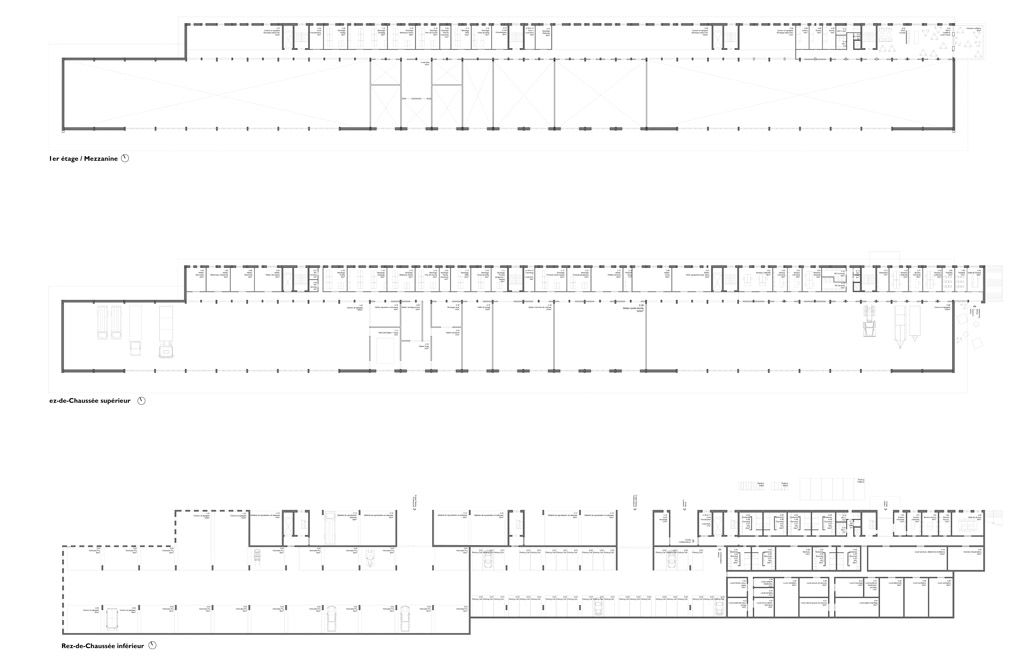

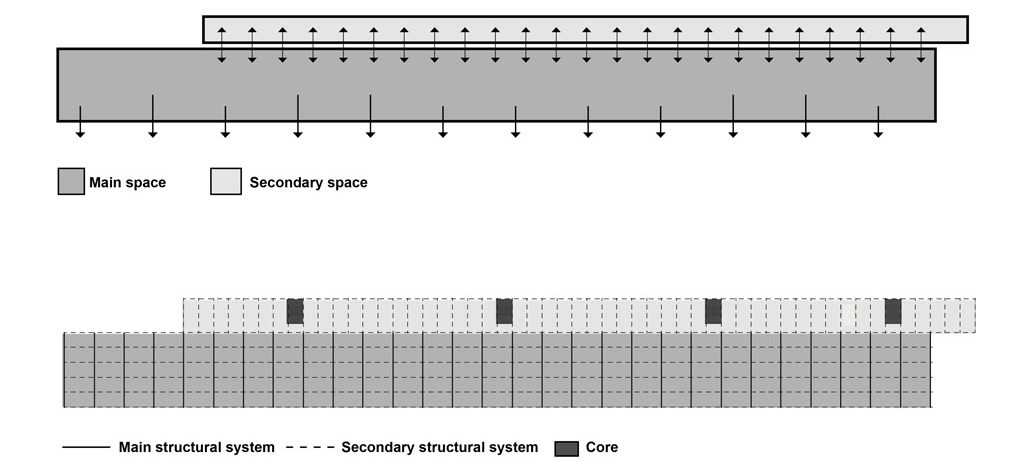

The new building is organized into two distinct parallel bands, each serving a specific function. The rear band houses all offices, workshops, services, and relaxation areas. The second, larger band comprises a spacious hall designed to accommodate trucks, trailers, and aggregates.. The parallel organization of these two bands allows for direct interaction, facilitating exchanges and workflow. People move between the zones primarily within the narrower band, while the large central square provides access and maneuvering space for activities in the hall.

Two Structural Frameworks for Two Distinct Functions

The division of the building into two sections optimizes its overall structure. The large hall boasts significant spans, up to 16.5 meters, with a spacing of 7.20 meters. In contrast, the rear section, 7 meters wide, optimizes beam sections by halving the spacing to 3.60 meters. Wooden beams are used in this area, while the slab is made of concrete to enhance thermal inertia. The small structural framework of this area enables and optimizes this structural system. Concrete vertical circulations also serve as bracing, ensuring necessary seismic stability and enhancing fire resistance of emergency routes at no additional cost.

Low-Tech Wooden Building

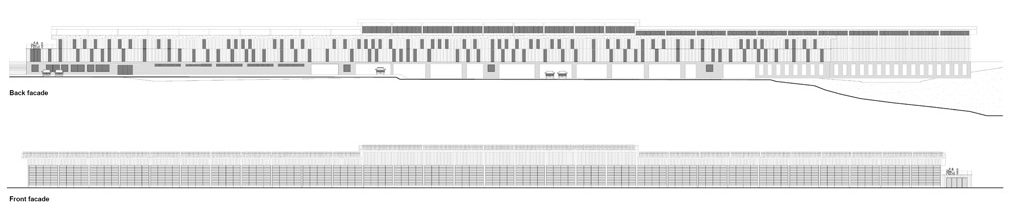

Primarily constructed of wood, the building’s structure and facade prioritize durability and rapid construction, favoring a modular approach (wood sandwich panels/window modules). This system offers flexibility, superior sound and thermal insulation, and economic advantages, significantly reducing long-term construction and maintenance costs.

An Evolving Project

The bulk of the project volume is concentrated in the northern site, freeing up a large flat area to the south. This spacious massing is surrounded by storage areas, salt silos, wash-through halls, and southern hydrogen production facilities. Currently offering ample freedom of movement, the central square can accommodate future densification in the southern band while retaining its current functionality. It may also serve as storage space or house certain programs like hydrogen production and parking.

Natural Ventilation

In the large truck hall, natural ventilation is crucial for maintaining a healthy and comfortable environment. Windows at the rear provide cross ventilation year-round, complemented by large roller doors, reducing environmental impact and associated energy costs.

Well-Ventilated Underground Parking

The parking, situated in the concrete base, features an open front with a dense fins grid. This setup offers weather protection, promotes air circulation, and helps maintain comfortable indoor temperatures year-round, reducing reliance on mechanical ventilation and artificial lighting.

Anticipated Demolition

The building is designed with a comprehensive life cycle approach, considering not just usage but also end-of-life scenarios and deconstruction. Material selection is pivotal in this regard. The integrated concrete base can be maintained, rehabilitated, or recycled, while the upper level, mainly wood and modular elements, facilitates easy deconstruction for recycling or reuse.

Program:

InfrastructureArchitect Partner:

M10 ArchitectesDate:

7 January 2024